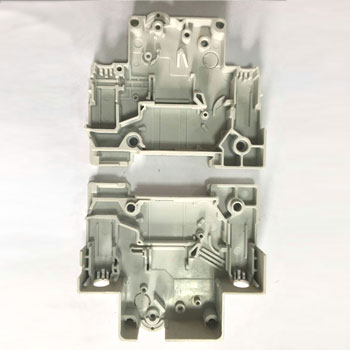

Correct maintenance knowledge of plastic mold

The service life of plastic mold is closely related to correct maintenance. In reality, there are too many cases of mold scrapping due to improper maintenance. Zhuoda company has been making molds for 10 or 20 years, but it is hard to remember how many such accidents have occurred. Some molds have been developed for more than 100000 yuan, but not many products have been produced. It is a pity that the molds have been torn apart. The following is a summary of the most basic knowledge of correct maintenance of plastic molds, so as to provide customers with basic maintenance habits and prolong the service life of molds。

1、 Mold maintenance before production

A. It is necessary to clean up the oil and rust on the surface of the mold, and check whether there are foreign matters in the cooling water hole of the casting mold, and whether there is water blockage.

B. It is necessary to check whether the arc in the die rubber mouth sleeve is damaged, whether there is residual foreign matter, whether the moving parts are abnormal and whether the movement is smooth.

2、 Mold maintenance in production

1. Check all guide pillars and guide sleeves of the mould every day to see if they are damaged, including the guide pillars, row position and other parts of the mould. Oil them regularly and maintain them on and off duty twice a day.

2. Clean the mold parting surface and exhaust groove of foreign matter, glue wire, foreign matter, oil, etc., and check whether the ejector pin of the mold is abnormal and oil regularly. Clean the parting surface and runner surface twice a day. Guide the pin once a day.

3. Regularly check whether the water channel of the mold is unblocked, and tighten all the fastening screws.

4. Check whether the limit switch of the mold is abnormal, and whether the inclined pin and inclined top are abnormal.

3、 Maintenance of shutdown mould

1. Before stopping the machine, the cooling water circuit must be closed first, the residual water in the water channel in the mold shall be blown out, and the surface of the mold shall be checked to see if there are residual glue and foreign matters on the surface of the mold. After the cleaning, the anti rust agent shall be sprayed evenly, and the relevant records shall be filled in accurately.