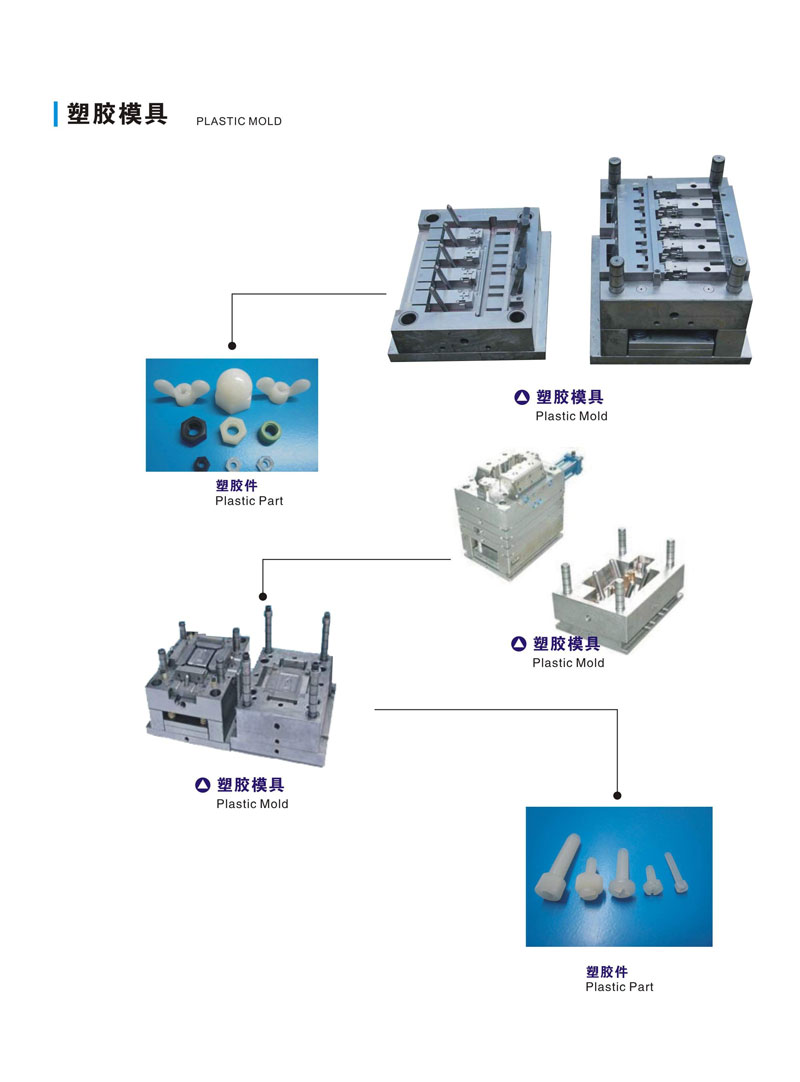

Plastic injection mold surface maintenance, it directly affects the surface quality of products, the focus is to prevent corrosion. After the mold has completed the production task, the residual injection molding should be carefully removed according to different injection molding methods. Copper rod, copper wire and soapy water can be used to remove the residual injection molding and other deposits in the mold, and then air dry. It is forbidden to clean iron wire, steel bar and other hard objects to avoid scratching the surface. If there are rust spots caused by corrosive injection molding, use grinding machine to grind and polish, and apply anti rust oil, and then store the mold in a dry, cool and dust-free place.

It can reduce the cost of production and maintenance, reduce the cost of production and maintenance, and reduce the cost of production and maintenance. Therefore, for injection molding products processing enterprises, in the current fierce market competition, good mold maintenance can help enterprises.