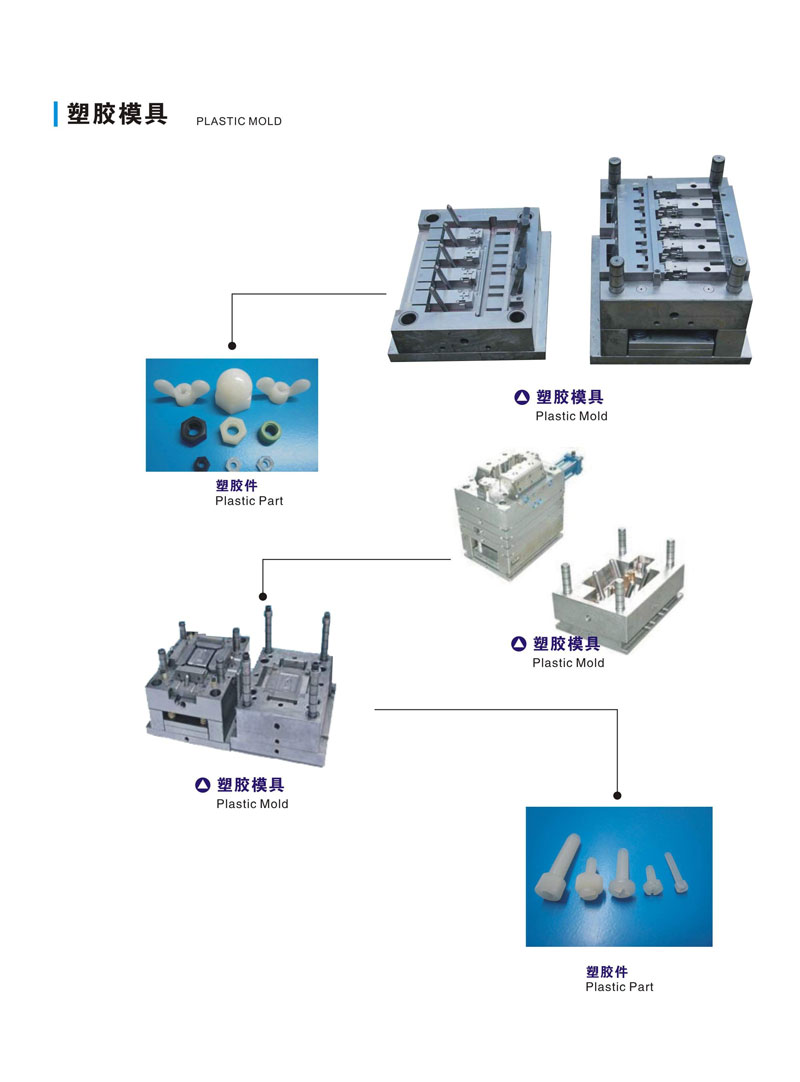

The exhaust groove must be set in plastic mold, otherwise it will affect the quality of injection molding and plastic parts. The number of exhaust grooves should be reasonable, too little is not conducive to exhaust, and too much is also harmful, which will lead to too much mold locking pressure acting on the parting surface of the mold cavity to open the exhaust groove, which is easy to cause deformation and even cracking of the parting surface.

In general, the distance between two exhaust grooves should not be less than 30mm. For high-precision plastic mold, perhaps the smallest flash is not allowed to exist. To completely remove the gas in the runner, set up an exhaust slot in the runner, do not bring the air in the gating system into the mold cavity. Silicon carbide abrasives can be used to shot peen the mating surface of parting surface.