Four elements of injection molding

1. Plastic mold 2. Injection molding machine 3. Plastic raw materials 4. Molding conditions

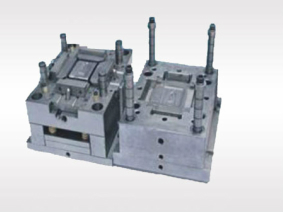

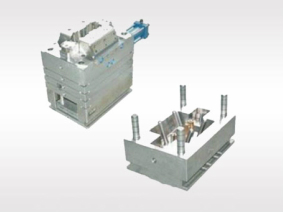

Most of them use two plate die, three plate die and some row die with slide block.

Basic structure: 1. Male mold (lower mold) male mold fixed plate, male mold auxiliary plate, thimble plate, male template. 2. Female mold (upper mold) female template, female mold fixed plate, rubber inlet ring and positioning ring. 3. Constant temperature system cools and stabilizes mold temperature.

The injection molding machine is mainly composed of plasticizing and injection device, mold closing device and transmission mechanism; the electric motor drives the motor, the motor drives the oil pump, the oil pump produces oil pressure, the oil pressure drives the piston, the piston drives the machinery, and the machinery produces action;

1. It can be divided into: 1. Horizontal injection molding machine; 2. Vertical injection molding machine; 3. Angular injection molding machine; 4. Multi color injection molding machine

2. It can be divided into: 1. Direct pressure injection molding machine; 2. Crankshaft type injection molding machine; 3. Direct pressing and crankshaft compound type

3. It can be divided into: 1. Plunger injection molding machine; 2. Single pass screw injection molding machine; 3. Reciprocating screw injection molding machine