Development trend of plastic mold processing technology

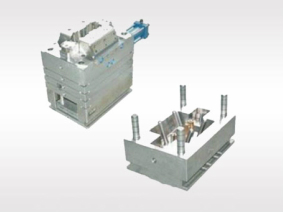

The first mock exam is the first mock exam. (1) the increasing size of mold parts and the high productivity of parts require a multi cavity mold, which results in the enlarging of the mold. The large tonnage die can reach 100 tons, a mold with hundreds of chambers and thousands of chambers, requiring large worktable for die processing equipment, Y axis Z stroke, heavy bearing, high rigidity and high consistency.

(2) The hardness of die steel material processed by die is high, which requires the die processing equipment to have thermal stability and high reliability.

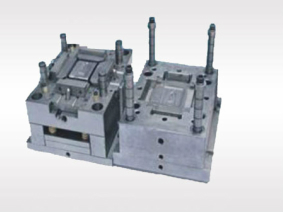

(3) For the complex cavity and multi-functional composite die, with the complexity of the product shape, it is necessary to improve the design and manufacturing level of the die. The multi-functional composite die with multiple grooves and materials formed or assembled into components in a set of die requires large amount of programming program, high cutting ability and high stability of high and deep hole cavity, which improves the machining difficulty.

(4) The precision of mold processing makes the complex and high efficiency of processing equipment more attractive. High speed milling has many advantages, such as Machinable high hard materials, stable processing, small cutting force, small temperature deformation of workpiece and so on.

(5) High dynamic accuracy. The static performance introduced by the machine tool manufacturer can not reflect the actual processing situation when the mold 3D surface is processed. High precision machining of three-dimensional surface of die and mold puts forward the requirement of high dynamic precision performance. High speed and high precision can only be realized with the combination of high rigidity, thermal stability, high reliability and high quality control system of the machine tool.

China is the center of the world's manufacturing industry and a big manufacturing country of metal casting mold industry. After years of rapid development, China's hardware casting mold industry market is prosperous, but the high-end products in the market still have a lot of defects, no matter in terms of quality, roughness, precision or structure, there is a long distance between them.

China's mold manufacturing industry has experienced many years of development, the production cycle of the mold industry is higher than the international level, but the product level is relatively low. According to Luo Baihui, this is mainly due to the accuracy of the casting mold, surface roughness of the cavity, life and structure. At present, the proportion of technical personnel in China's foundry mold enterprises is low, the level is also low, and do not attach importance to product development, often in a passive position in the market.

With the continuous growth of China's economy, the casting industry will maintain a high growth rate and drive the development of the casting mold manufacturing industry. The casting mold market is extremely active. Due to the low cost of mold production in China, with the improvement of mold manufacturing technology and quality. Not only can reduce the mold import, but also may gradually open the foreign market, mold export will have a great development.