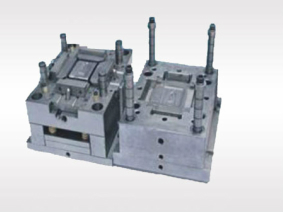

Determine mold material and select standard parts.

In the selection of die materials, in addition to considering the accuracy and quality of products, but also combined with the actual ability of the mold factory processing and heat treatment to give the correct choice. In addition, in order to shorten the manufacturing cycle, the existing standard parts should be used as much as possible.

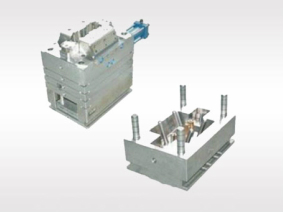

Parts processing and mold assembly.

In addition to giving the best structure and reasonable tolerance in the design of injection mold accuracy, parts processing and mold assembly are very important. Therefore, the choice of machining precision and processing method is absolutely dominant in the two-color injection molding. The dimensional error of molded products is mainly composed of the following parts:

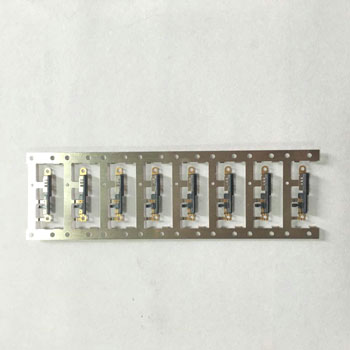

1. The manufacturing error of mould is about one third。

2. The error caused by die wear is about one sixth。

3. The error caused by uneven shrinkage of molded parts is about one third。

4. The error caused by the inconsistency between the expected shrinkage and the actual shrinkage is about one sixth。