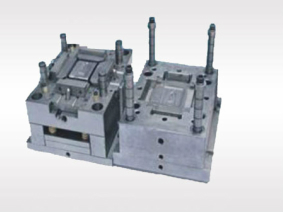

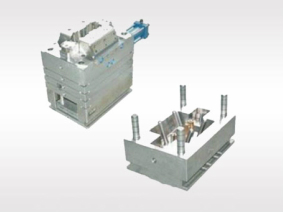

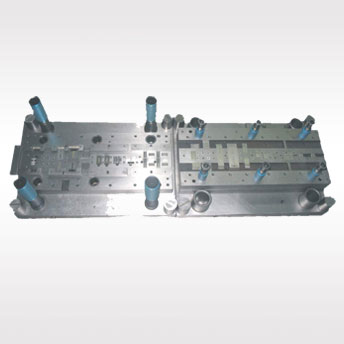

The utility model relates to a combined plastic mold for pressure molding, extrusion molding, injection molding, blow molding and low foaming molding, which mainly includes a female die with a variable cavity composed of a female die composite base plate, a female die assembly and a female die combination card plate, and a punch with a variable core composed of a punch combination base plate, a punch assembly, a punch combination card plate, a cavity cut-off component and a side section composite plate. Coordinate change of punch, die and auxiliary molding system. It can process series plastic parts of different shapes and sizes. Plastic processing industry and plastic molding machine matching, giving plastic products with complete configuration and accurate size of tools. Due to the variety and processing methods of plastics, the structure of plastic molding machines and plastic products is complicated and simple, so the types and structures of plastic molds are also diverse.

With the rapid development of plastic industry and the continuous improvement of strength of general and engineering plastics, the application scope of plastic products is also expanding, and the consumption of plastic products is also rising.

Plastic mold is a kind of tool for producing plastic products. It is composed of several groups of parts, and the combination has forming cavity. During injection molding, the mold is clamped on the injection molding machine, and the molten plastic is injected into the injection mold cavity, and cooled and shaped in the cavity. Then, the upper and lower molds are separated, and the products are ejected from the mold cavity through the ejection system. Finally, the mold is closed for the next injection. The whole injection process is cyclic.