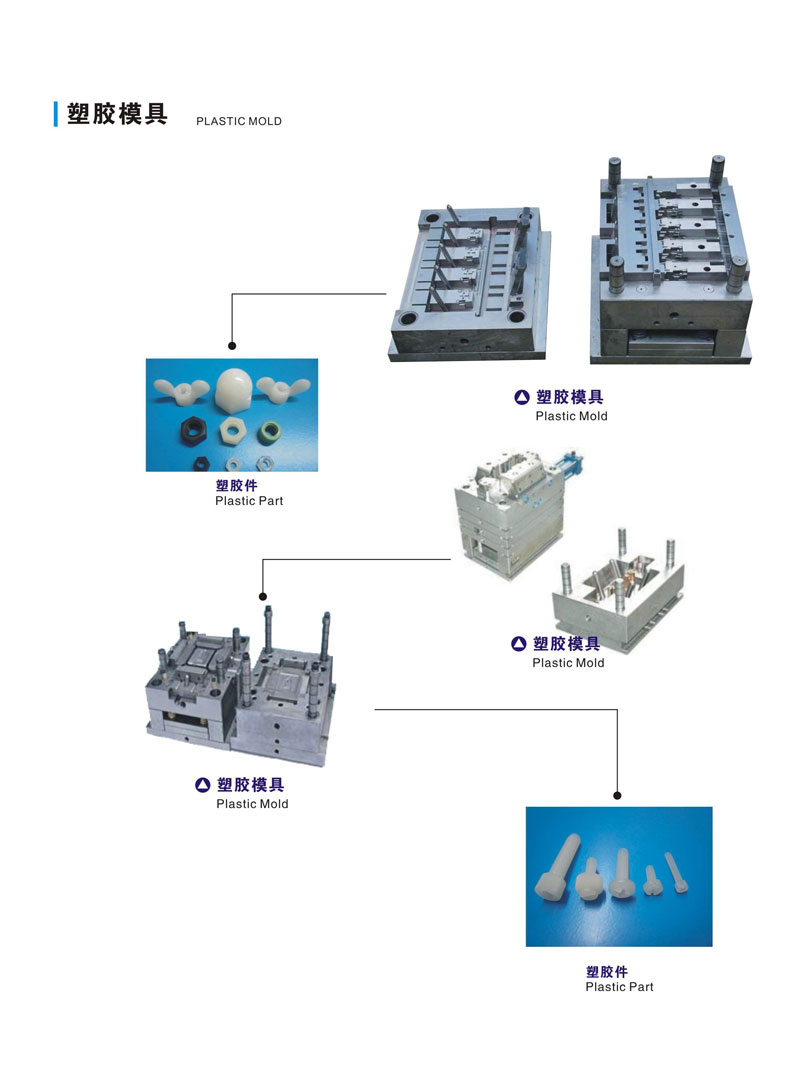

The manufacturing of die and mould usually goes through forging, cutting and heat treatment. In order to ensure the manufacturing quality of the die and reduce the production cost, the material should have good malleability, machinability, hardenability, hardenability and grindability; it should also have small oxidation, decarburization sensitivity and quenching deformation cracking tendency.

1. Malleability

It has low hot forging deformation resistance, good plasticity, wide range of forging temperature, low tendency of cold cracking and precipitation of network carbide.

2. Annealing process

The spheroidizing annealing temperature range is wide, the annealing hardness is low and the fluctuation range is small, and the spheroidizing rate is high.

3. Machinability

Large cutting parameters, low tool loss and low surface roughness.

4. Oxidation and decarburization sensitivity

When heated at high temperature, the oxidation resistance capacity is good, the decarburization rate is slow, the heating medium is not sensitive, and the pitting tendency is small.

5. Hardenability

It has uniform and high surface hardness after quenching.

6. Hardenability

After quenching, a deeper hardening layer can be obtained, which can be hardened by using mild quenching medium.

7. Tendency of deformation and cracking during quenching

The volume change of conventional quenching is small, the shape warpage and distortion are slight, and the abnormal deformation tendency is low. The cracking sensitivity of conventional quenching is low, and it is not sensitive to quenching temperature and workpiece shape.

8. Grindability

It is not sensitive to the quality and cooling conditions of grinding wheel, and it is not easy to cause grinding damage and grinding cracks.